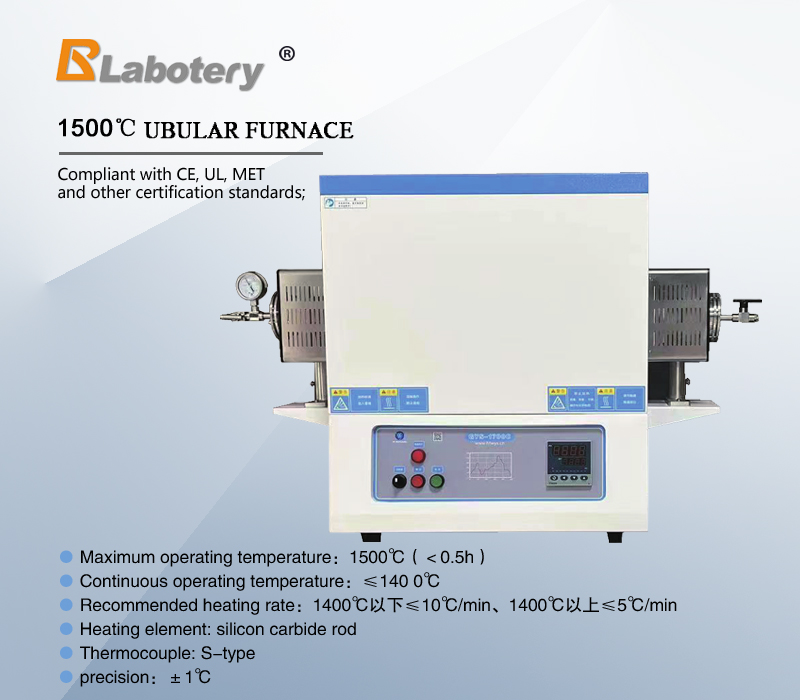

1500 ℃ tubular furnace

1、Brief introduction

This tube furnace can reach a maximum temperature of 1500 ℃; Adopting a double-layer shell structure and equipped with an air-cooled system; The furnace is made of high-purity alumina fiber material to minimize energy loss to the greatest extent possible; The surface of the inner furnace is coated with high-temperature alumina imported from the United States, which can improve the reflectivity and heating efficiency of the equipment, as well as extend the service life of the instrument. It is equipped with overheating and thermocouple protection; This furnace has the advantages of temperature field balance, low surface temperature, fast temperature rise and fall rate, and energy saving. It is a suitable product for sintering or annealing (under vacuum or inert gas protection) of new material samples in universities, research institutes, and industrial and mining enterprises.

2、 Technical data

● Maximum operating temperature: 1500 ℃ (< 0.5h)

● Continuous operating temperature: ≤ 1400 ℃

● Recommended heating rate: ≤ 10 ℃/min below 1400 ℃, ≤ 5 ℃/min above 1400 ℃

● Heating element: silicon carbon rod

● Thermocouple: S-type

● Temperature control accuracy: ± 1 ℃

● Temperature control method: including a YD858 temperature controller; PID control and self-tuning regulation, intelligent 50 segment programmable control, with super temperature and couple breaking alarm function.

Certification standards and core components: The core components of the entire machine comply with CE, UL, MET and other certification standards;

The core components include ABB electrical components, UL certified wires and cables, Omega, Yudian, Continental instruments, etc.

| model | GYS-1500C-S | GYS-1500C |

| maximum temperature | 1500℃(<0.5h) | |

| Heating zone length | 170mm | 300mm |

| Quartz tube size | φ50×800mm/φ60×800mm | Φ60×1000mm/φ80×1000mm/φ100×1000mm |

| rated power | 2.6KW | 5.6KW |

| rated voltage | 220V | |

| External dimensions | 850mm×420mm×670mm | 1010mm×510mm×780mm |

| weight | 55KG | 155KG |